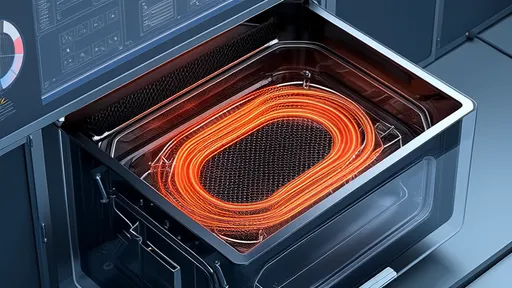

The phenomenon of vacuum impregnation represents a fascinating intersection of food science and physics, offering a window into the complex dynamics of how flavors traverse cellular barriers. At its core, this process leverages pressure differentials to drive the penetration of seasoning solutions into the interstitial spaces of plant or animal tissues, fundamentally altering their sensory profiles. Unlike conventional marination, which relies heavily on time and concentration gradients, vacuum impregnation accelerates diffusion through a deliberate manipulation of the environment, creating a vacuum that removes air from tissue pores before restoring atmospheric pressure to force the infusion of liquids. This method not only enhances flavor intensity but also improves texture and nutritional value, making it a subject of keen interest for both industrial applications and culinary innovation.

Understanding the kinetics of this process requires a deep dive into the principles of diffusion and porous media. When a food substrate is placed under vacuum, the air entrapped within its cellular structure expands and is partially expelled. Upon the reintroduction of pressure, the external seasoning solution is driven into these vacated spaces. The rate at which this occurs—the diffusion kinetics—is governed by factors such as the porosity of the material, the viscosity of the impregnating solution, the magnitude of the pressure change, and the interfacial properties between the solid matrix and the liquid. These variables interact in a complex dance, determining how quickly and deeply flavors migrate.

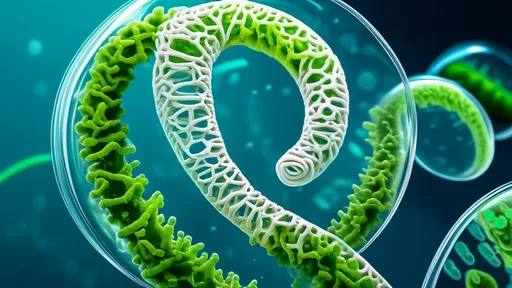

The cellular architecture of the food itself acts as the primary governor of diffusion. Plant tissues, for instance, are composed of cells surrounded by pectin-rich middle lamellas and air-filled intercellular spaces. The size, distribution, and connectivity of these pores create a unique pathway for liquid movement. In animal tissues, the structure is less porous but still contains channels and gaps between protein fibers or fat globules. The vacuum impregnation process effectively maps itself onto this inherent microstructure, with the rate of seasoning infusion being directly proportional to the ease with which the liquid can navigate this labyrinthine network.

Mathematical modeling of these kinetics often draws from Fick's laws of diffusion, but must be adapted to account for the non-ideal nature of biological materials. The effective diffusivity is not a constant but a parameter influenced by tissue deformation during the pressure cycles, the possible interaction (e.g., osmosis) between the seasoning solutes and the intracellular fluids, and the gradual saturation of the pore space. Researchers employ sophisticated models that couple hydrodynamic flow with diffusion to predict how the concentration of seasoning evolves within the material over time, providing valuable insights for optimizing the process.

The composition of the seasoning solution is another critical lever controlling the diffusion rate. Solutions with lower viscosity obviously flow more readily, but the molecular size of the flavor compounds plays an equally pivotal role. Smaller molecules, like salts and simple sugars, diffuse rapidly, while larger molecules, such as certain proteins or polysaccharides used for flavor, move more sluggishly. Furthermore, the concentration gradient, a classic driver of diffusion, is dynamically affected by the process itself. As the front of seasoning solution advances, it dilutes the concentration at the interface, potentially slowing down subsequent infusion unless the external solution is highly concentrated or continuously replenished.

Temperature serves as a powerful accelerator in this system. Raising the temperature of the process does two things: it decreases the viscosity of the impregnating liquid, making it flow more easily, and it increases the kinetic energy of the molecules, prompting more vigorous and rapid movement. However, this benefit must be balanced against potential drawbacks. Excessive heat can damage the cellular structure, causing it to soften or collapse, which might ironically hinder diffusion by closing off pores or lead to undesirable textural changes in the final product. It can also degrade heat-sensitive volatile compounds responsible for delicate flavors and aromas.

In industrial settings, mastering these kinetics is paramount for efficiency and consistency. The vacuum level, holding time, pressure restoration rate, and number of cycles are all finely tuned parameters. For a porous vegetable like mushroom, the process might be swift, taking only a few minutes. For a denser fruit like apple or a piece of meat, it may require longer cycles or repeated vacuum-pressure pulses to achieve the desired depth of flavor penetration. The ultimate goal is to achieve a uniform distribution of seasoning without compromising the structural integrity of the food, ensuring every bite delivers the intended taste experience.

Looking beyond mere flavoring, the implications of vacuum impregnation kinetics are vast. This technology is pivotal in developing functional foods, where nutrients, vitamins, or probiotics are impregnated into food matrices to create healthier options. The same principles that dictate how salt moves into a piece of chicken also govern how calcium might be infused into a fruit snack to enhance its nutritional profile. The precision offered by controlling these diffusion rates opens up new frontiers in food design, allowing for the creation of products with tailored sensory and health properties that were previously unimaginable.

In conclusion, the kinetics of seasoning diffusion during vacuum impregnation is a rich field of study that sits at the crossroads of engineering, material science, and gastronomy. It transforms the simple act of flavoring into a predictable, controllable process. By deciphering the language of pressure, porosity, and viscosity, scientists and food technologists can not only replicate the depth of flavor achieved by traditional slow methods but also exceed it, creating novel food experiences and contributing to the advancement of global food technology in an increasingly flavor-driven world.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025