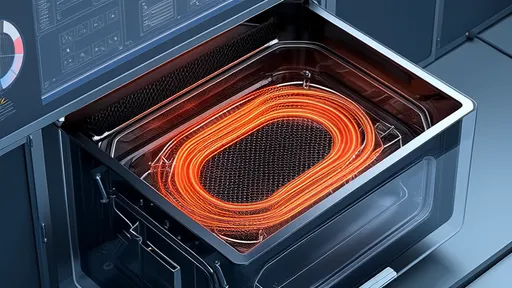

The convection oven represents one of the most significant advancements in modern cooking technology, blending principles of fluid dynamics and heat transfer to achieve remarkable efficiency and uniformity in thermal processing. Unlike traditional radiant ovens, which rely primarily on static, ambient heat, convection ovens employ actively circulated air to enhance thermal distribution and accelerate cooking times. This dynamic approach to oven design has transformed everything from home kitchens to industrial food production, offering improved energy efficiency, reduced cooking durations, and superior culinary results. The optimization of these systems hinges on a delicate interplay between aerodynamic behavior and thermodynamic exchange—a synergy that continues to drive innovation in appliance engineering.

At the core of every convection oven is a fan system that forces the movement of heated air throughout the cooking chamber. This circulation is not merely about blowing hot air around; it is a carefully engineered process intended to disrupt the boundary layer of stagnant air that naturally forms around food. In traditional ovens, this insulating layer can lead to uneven heating—overcooked surfaces and undercooked centers. By maintaining a consistent flow of air, convection ovens minimize temperature gradients, enabling heat to penetrate more evenly and rapidly. The result is food that cooks more quickly and uniformly, with desirable characteristics such as crisp exteriors and moist interiors, whether roasting, baking, or broiling.

The efficiency of a convection oven is deeply rooted in the principles of fluid mechanics. The behavior of air within the oven cavity can be modeled as a internal flow system, where parameters such as velocity, pressure, and turbulence must be optimized to achieve desired performance. Laminar flow, while orderly, is often insufficient for effective heat transfer due to its low mixing capability. Thus, engineers deliberately introduce elements that promote turbulence—strategically placed baffles, impingement jets, or variable-speed fans—to enhance convective heat transfer coefficients. The design of the fan itself, including its blade shape, rotational speed, and positioning, is critical to generating the necessary airflow patterns without creating unwanted noise or consuming excessive energy.

Thermal exchange in convection ovens operates through forced convection, a mode of heat transfer substantially more efficient than natural convection or radiation. The rate of heat transfer is governed by factors such as the temperature difference between the air and the food, the surface area exposed to airflow, and the properties of the air itself—including its density, viscosity, and thermal conductivity. By increasing air velocity, the convective heat transfer coefficient is elevated, leading to faster cooking. However, this must be balanced against the risk of drying out food or causing excessive evaporation. Sophisticated modern ovens often incorporate humidity control or steam injection to mitigate these effects, preserving moisture while still leveraging the benefits of circulated heat.

Energy optimization remains a primary goal in convection oven design. The reduced cooking times directly translate to lower energy consumption, a vital consideration in both household and commercial settings. Studies have shown that convection ovens can operate at temperatures up to 25°C lower than conventional ovens while achieving similar or better results, further contributing to energy savings. Additionally, the improved homogeneity of heating means that preheating times can be shortened, and temperature recovery after door opening is faster. These efficiencies are maximized when the oven is well-insulated and when the airflow path is engineered to minimize dead zones and recirculation losses.

Advanced computational fluid dynamics (CFD) simulations have become indispensable in the development of high-performance convection ovens. Through virtual modeling, engineers can visualize and analyze complex airflow patterns, temperature distributions, and heat flux densities without the need for costly physical prototypes. These simulations allow for iterative refinement of fan placement, vent configurations, and heating element layouts to eliminate hotspots or cold spots. The integration of multi-speed fans, dual convection systems (such as top and bottom air circulation), and even 3D air flow technologies in premium models are direct outcomes of such sophisticated analysis, pushing the boundaries of what convection cooking can achieve.

Material selection also plays a crucial role in the thermal efficiency and durability of convection ovens. Interior surfaces are often coated with materials that have high emissivity and low thermal mass to facilitate quick heating and easy cleaning. Heating elements are designed for rapid response and even output, while fans must withstand high temperatures without warping or degrading. The use of stainless steel, ceramic, and advanced polymers in critical components ensures that the oven not only performs efficiently but also maintains that performance over its lifespan despite frequent thermal cycling.

Looking forward, the evolution of convection ovens is likely to embrace greater intelligence and adaptability. Smart sensors that monitor internal food temperature, humidity, and even color or texture can provide real-time feedback to dynamically adjust fan speed and heating power. Machine learning algorithms may one day predict optimal cooking parameters based on the type and quantity of food, further enhancing efficiency and consistency. As environmental concerns grow, the focus on energy-saving technologies will intensify, potentially leading to ovens that integrate heat recovery systems or renewable energy sources. The marriage of fluid mechanics and heat transfer science will continue to be essential, driving innovations that make convection cooking even more effective, economical, and accessible.

In summary, the convection oven is a quintessential example of applied thermodynamics and fluid dynamics, where every component—from the fan to the heating element to the cavity geometry—is optimized to work in concert. The result is a kitchen appliance that not only saves time and energy but also elevates the quality of cooked food. Through continued research and technological integration, the humble convection oven stands poised to remain at the forefront of culinary innovation for years to come.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025