The culinary world is perpetually in flux, with innovation often arriving from the most unexpected quarters. One such frontier, emerging not from the stovetop but from the laboratory, is the application of ultrasonic cavitation. This sophisticated physical phenomenon, long a tool in industrial cleaning and medical therapy, is now demonstrating a profound capacity to transform the very architecture of our food. By harnessing high-frequency sound waves, chefs and food scientists are beginning to manipulate textures, intensify flavors, and accelerate processes in ways previously confined to science fiction, heralding a new era of precision gastronomy.

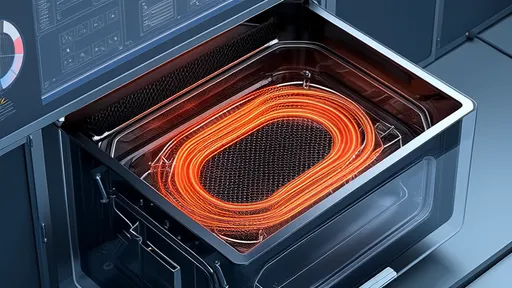

At its core, ultrasonic cavitation is a process initiated by sound waves traveling through a liquid medium at frequencies beyond the upper limit of human hearing, typically above 20 kHz. When these high-frequency waves propagate, they consist of alternating cycles of compression and rarefaction. During the rarefaction, or negative-pressure, cycle, the forces acting on the liquid can overcome its inherent tensile strength, tearing it apart to form microscopic voids. These bubbles, or cavities, are filled with vapor and gases dissolved in the liquid. They are transient entities, existing for mere microseconds before the subsequent compression cycle violently forces them to collapse in on themselves. It is this implosion that is the heart of the matter. The collapse is so rapid and energetic that it creates localized spots of extreme conditions—temperatures soaring to thousands of degrees Kelvin and pressures exceeding hundreds of atmospheres, accompanied by powerful shockwaves and liquid jets. This maelstrom of energy, contained within a microscopic scale, is the engine of change for any material suspended within the liquid, be it a vegetable cell or a piece of meat.

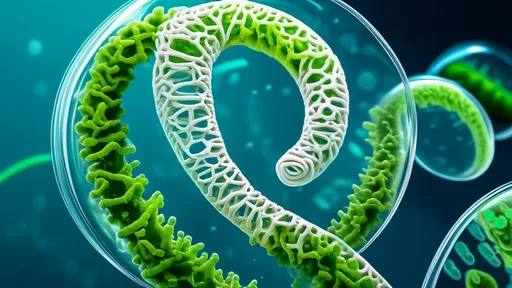

The interaction between these collapsing cavitation bubbles and biological tissue is where the culinary magic unfolds. Plant-based foods, with their rigid cellular structures held together by pectin and cellulose, are particularly susceptible. The intense shear forces and micro-jets generated by cavitation act like a microscopic army, physically eroding cell walls and breaking down the middle lamella that cements adjacent cells together. This mechanical assault effectively tenderizes tough vegetables, making them cook faster and feel more palatable. Furthermore, this cellular disruption is a boon for extraction processes. The breakdown of cell walls acts as a pre-treatment, liberating intracellular compounds like pigments, antioxidants, and oils without the need for excessive heat or solvents. This leads to more vibrant colors, more potent flavors, and higher yields in processes like oil extraction or the creation of natural food colorings, all while better preserving heat-sensitive nutrients.

When applied to animal proteins, the effects of ultrasonic cavitation are equally transformative but operate through a different mechanism. Muscle tissue is primarily composed of long protein fibers bundled together by connective tissue. The shockwaves from collapsing bubbles cause physical damage at a microscopic level, shearing and fracturing these protein structures. This results in a significant tenderizing effect, breaking down the toughness often associated with certain cuts of meat. More subtly, the energy input can also cause partial denaturation and unfolding of the protein molecules themselves. This alteration of the protein's tertiary and quaternary structures enhances its water-holding capacity, leading to juicier end products. It also increases the number of binding sites available, which can improve the efficacy of marination. Brines and marinades can penetrate deeper into the tissue in a fraction of the time, allowing flavors to infuse more thoroughly and efficiently than through passive diffusion alone.

Beyond simple tenderizing and marinating, ultrasonic cavitation is revolutionizing foundational culinary techniques. One of its most promising applications is in the realm of emulsification. Creating a stable emulsion, such as a vinaigrette or mayonnaise, traditionally requires vigorous whisking or mechanical homogenization to break one liquid phase into incredibly tiny droplets and disperse it throughout another. The extreme shear forces generated by cavitation bubbles achieve this with unparalleled efficiency, producing emulsions with droplet sizes in the nanometer range. These nanoemulsions are exceptionally stable, resisting separation for far longer than their traditionally prepared counterparts, and often possess a uniquely creamy, smooth mouthfeel that is difficult to achieve by other means.

Another significant application is in the acceleration of aging and curing processes. For instance, in the production of cured meats or alcoholic spirits, time is a key ingredient. Ultrasonication can dramatically hasten these slow biochemical reactions. The energy from cavitation enhances mass transfer, allowing salts, sugars, and smoke compounds to diffuse into the product much faster. Simultaneously, it can stimulate the activity of enzymes responsible for developing flavor or trigger oxidative reactions that contribute to the characteristic taste of aged products. This allows producers to achieve in hours what might naturally take weeks or months, without merely being a shortcut; the process can be fine-tuned to develop specific flavor profiles, offering a new tool for controlled flavor development.

As with any powerful technology, the adoption of ultrasonic cavitation in food processing is not without its challenges and considerations. Scaling the technology from a laboratory benchtop to industrial production lines requires careful engineering to ensure consistent and uniform energy distribution throughout a large volume of food. There is also the question of potential unintended consequences. The violent process could theoretically promote oxidation of sensitive lipids or vitamins, or even generate minute amounts of free radicals, though research in this area is ongoing. The regulatory landscape is also evolving, as food safety agencies worldwide work to establish guidelines for this novel non-thermal processing technology to ensure all applications are safe for consumer health.

Despite these hurdles, the potential of ultrasonic cavitation is driving rapid innovation. Researchers are experimenting with variable frequencies and power settings to target specific outcomes, from gently extracting delicate aromas to thoroughly tenderizing tough muscle. The equipment itself is becoming more refined, moving from large, immobile industrial tanks to more modular and even handheld devices that could one day find a place in professional restaurant kitchens. This democratization of the technology could open the door for chefs to become true alchemists, manipulating texture and flavor on demand with scientific precision.

In conclusion, ultrasonic cavitation represents far more than a novel kitchen gadget; it is a fundamental shift in our approach to manipulating food. By leveraging the immense power of controlled microscopic implosions, we are gaining unprecedented mastery over the structural components of ingredients. This technology allows us to enhance natural flavors, create novel textures, and optimize processes that have remained largely unchanged for centuries. It stands as a brilliant testament to the fusion of science and culinary art, pushing the boundaries of what is possible on a plate and offering a glimpse into a future where food can be engineered for optimum enjoyment, nutrition, and sustainability. The sound of the future of food is, quite literally, a high-frequency hum.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025